Four Ways to Leverage Takt Time for Your Manufacturing Process

Takt Time in Your Process

Takt time is much more than a simple metric or calculation. To understand why, let’s explore four different ways that takt time can impact your manufacturing process.

| Area of Impact | How Takt Time Helps |

|---|---|

| Capacity Planning | Understand and quantify differences between customer needs (takt time) and manufacturing capabilities (operable takt time). |

| Process Design | Ensure you meet customer demand in the medium to long term by changing operable takt time through changes to your process and/or equipment. |

| Production Scheduling | Ensure you meet customer demand in the short to medium term by changing available production time through changes to shift schedules and/or process staffing. |

| Plant Floor Operations | Establish a real-time production target based on operable takt time that enables your plant floor team to “win the shift.” |

1. Capacity Planning

Capacity planning helps you determine how much production capacity you will need to meet customer demand. You can think of it as comparing:

- Takt Time: The pace that exactly meets customer demand given available production time. This is a customer-focused metric.

- Operable Takt Time: The pace you can actually achieve with your current process and equipment. This is a manufacturing-focused metric.

Any discrepancy between the two will lead to a suboptimal result, which can be either:

- Unmet Customer Demand (if operable takt time is too slow)

- Excess Inventory (if operable takt time is too fast)

Therefore, the goal of capacity planning is to strategize the best way to align takt time (driven by demand) with operable takt time (driven by your manufacturing process). The associated time horizon is typically medium to long (months to years), since in order to accurately calculate takt time, you need a clear understanding of demand over time and how much demand you intend to meet now and in the future.

Once customer demand is forecast (and thus fixed), there are two strategies to bring takt time and operable takt time into alignment:

- Change the process (changes operable takt time independently of planned run time)

- Change the schedule (changes takt time by changing planned run time)

2. Process Design

Process design establishes your operable takt time, which is the pace you can actually achieve on a sustained basis with your current process and equipment.

- Over the short term, operable takt time can usually only be incrementally improved (e.g., through improvement initiatives that change the existing process)

- Over the long term, operable takt time can be more substantially improved (e.g., by modifying the design of your equipment)

There are very interesting parallels between ideal cycle time and operable takt time when thinking about the throughput of your process.

- Ideal cycle time is often defined as nameplate capacity. It is the fastest that your process can run under perfect conditions. Running at ideal cycle time with no stops or defects is perfect production.

- Operable takt time is also a type of cycle time. It is the fastest that your process can run in the real world on a sustained basis. It includes budgeted time for losses that occur during planned run time (small stops, slow cycles, defects, downtime). Running at operable takt time is attainable production.

Keep in mind that it is nearly impossible for processes to run continuously and perfectly. Doing so would represent 100% performance (every cycle as fast as possible), 100% availability (always running with no downtime), and 100% quality (no defects). Therefore, it is important to budget losses into your operable takt time so you have an accurate picture of real-world capacity and throughput.

3. Production Scheduling

Production scheduling enables you to adjust takt time to better meet customer demand in the short to medium term by changing available production time (referred to as planned run time from a manufacturing perspective) either:

- Directly through changes to shift schedules

- Indirectly through changes to the number of people working at the process

Since customer demand is usually treated as fixed, the only “lever” you have to pull in changing takt time is planned run time.

In order to accommodate fluctuations in demand, schedule:

- Fewer shifts and/or operators when demand falls for a given product

- More shifts and/or operators when demand rises for a given product

4. Plant Floor Operations

The plant floor is where takt time is transformed from concept to practice. It is where the rhythm of production is executed. In lean manufacturing terms, it is the place of “gemba” (the actual spot or scene).

Applying Takt Time to the Plant Floor

There are important nuances to consider when applying takt time to the plant floor.

The first is whether takt time should be interpreted as a strict pace that is not be exceeded. For the vast majority of manufacturers, the answer is no. Unless you need to constrain pace due to design constraints, such as to control defects, operable takt time should be considered an improvable metric. You want your operators to have an opportunity and incentive to improve. Production time that is recovered can be used for other productive activities, including process improvement and production of other parts.

The second is how to translate takt time into something concrete for operators. There is a valuable opportunity here, which is using operable takt time to drive real-time targets so operators know exactly how they are performing against expectations.

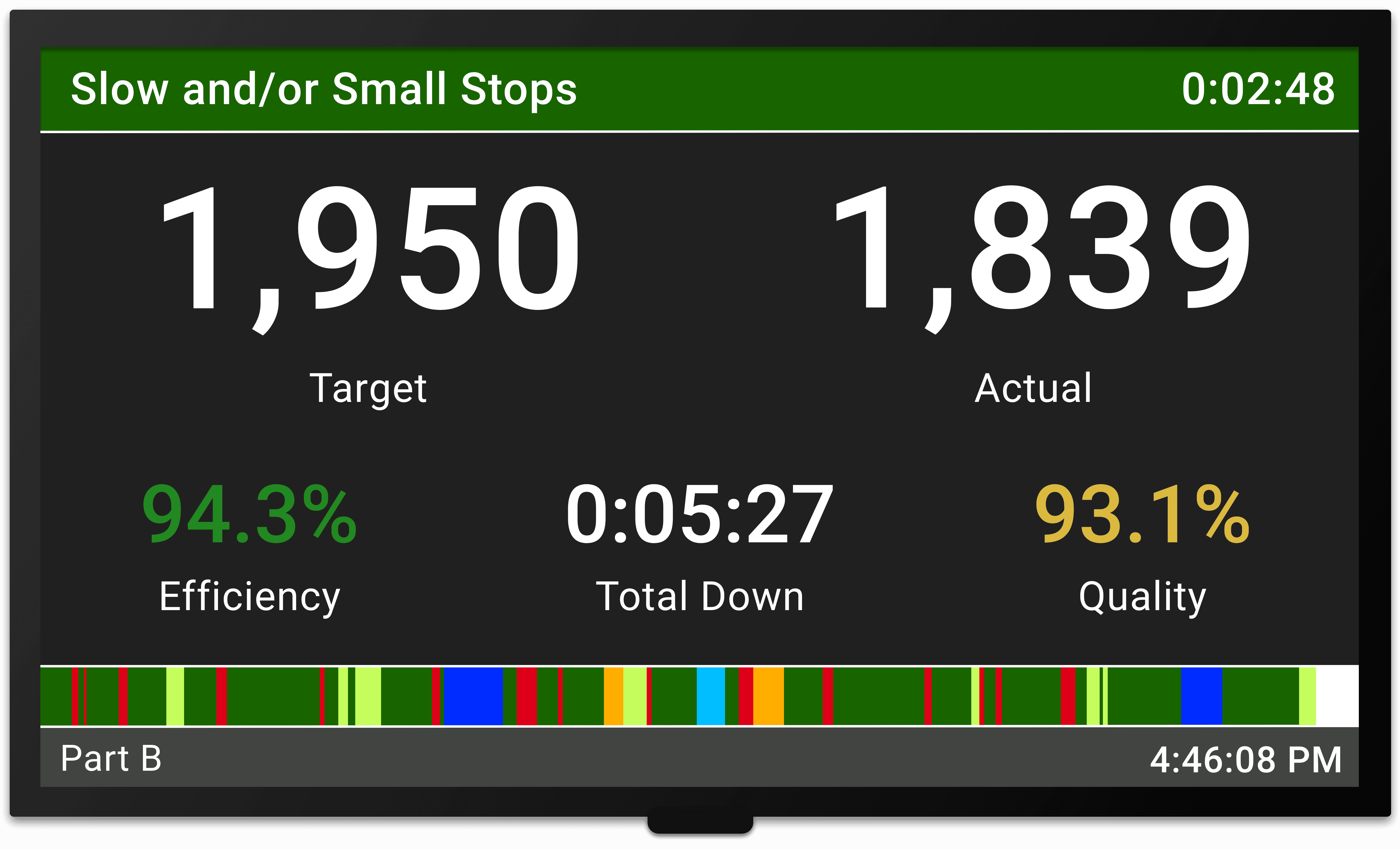

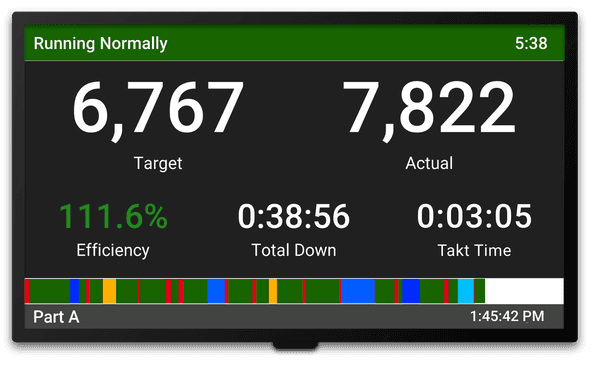

Leveraging a Plant Floor Scoreboard

Rather than using a whiteboard or a simple pace timer, which is more or less the equivalent of a repeating stopwatch, we recommend a scoreboard with TAED: Target, Actual, Efficiency, Downtime. The beauty of TAED is that it transforms takt time into an opportunity for operators to “win the shift.” It motivates and informs your operators by enabling them to see exactly where they stand in real time. Target is a dynamic value that lets operators know where they should be right now. Unlike a static goal, the target value is always relevant.

More specifically, a TAED scoreboard displays the following real-time metrics:

| Metric | Description |

|---|---|

| Target Count | A target for good parts driven by operable takt time. Each time the operable takt time is reached, the target count increases. |

| Actual Count | The actual number of good parts completed. |

| Efficiency | Calculated as actual count divided by target count. 100% or higher means your team is “winning the shift.” |

| Downtime | Included as it is by far the largest source of lost time for most manufacturers. It’s good for operators to keep eyes on this metric. |

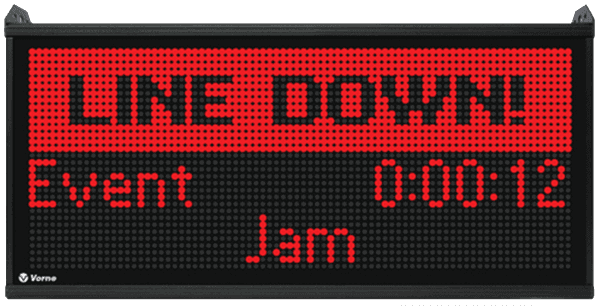

And speaking of downtime - much like how an Andon uses a visual indicator to highlight instances of downtime, the TAED scoreboard should also highlight down events and prompt the operator to select a reason or use integration tools to retrieve that information automatically.

Many companies see an immediate improvement in productivity simply by setting a challenging but attainable target (via operable takt time) and showing operators the status of production in real time.

WHAT YOU SHOULD DO NEXT...

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

Learn More2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

DOWNLOAD FREE OEE TOOLS3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.